VIMS develops underwater robot to assist in oil-spill cleanup

Prototype uses sound waves to help gauge thickness of slicks

One big challenge facing cleanup crews during an offshore oil spill—such as 2010’s Deepwater Horizon disaster in the Gulf of Mexico—is determining just how much oil is involved. Researchers at the Virginia Institute of Marine Science have now developed a remotely operated underwater vehicle to someday assist in this key aspect of the oil-spill response.

Project leader Paul Panetta, a scientist with Applied Research Associates, Inc., and an adjunct professor at VIMS, says “Gauging the volume of a spill, and the extent and thickness of its surface slick, are usually done by visual surveillance from planes and boats, but that can be quite difficult. Our ROV [remotely operated vehicle] uses acoustic signals to help more easily locate and focus on the thickest part of the slick.”

The difficulty of assessing spill size and volume is likely to increase as oil exploration and recovery moves into Arctic waters, where ice and bad weather can hinder both access and visibility. Funding for Panetta’s work comes from the Oil Spill Response Research Program, part of the U.S. Interior Department’s Bureau of Safety and Environmental Enforcement. The program funds research to improve the response to Arctic spills, and operates the 2.6 million-gallon Ohmsett Wave Tank in Leonardo, New Jersey where Panetta’s robot was initially prototyped and will now be delivered for use by Ohmsett staff and other research teams.

The difficulty of assessing spill size and volume is likely to increase as oil exploration and recovery moves into Arctic waters, where ice and bad weather can hinder both access and visibility. Funding for Panetta’s work comes from the Oil Spill Response Research Program, part of the U.S. Interior Department’s Bureau of Safety and Environmental Enforcement. The program funds research to improve the response to Arctic spills, and operates the 2.6 million-gallon Ohmsett Wave Tank in Leonardo, New Jersey where Panetta’s robot was initially prototyped and will now be delivered for use by Ohmsett staff and other research teams.

“Our ROV will measure the thickness of experimental slicks at Ohmsett to aid in developing and testing oil-spill-response tools,” says Panetta. “It will also provide a test platform for developing other sensors and for field applications. It’s one step along the path to developing platforms for use in the ocean to measure slick thickness and other oil properties using acoustics.”

The Ohmsett tank is the official National Oil Spill Response Research Facility. Many of today's oil-spill cleanup products and techniques have been developed and tested there.

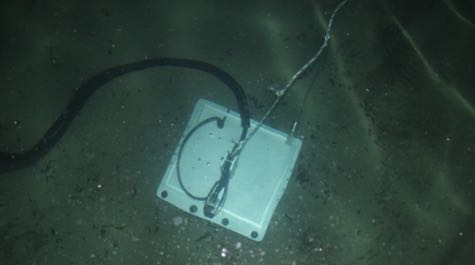

Acoustic Slick Thickness ROV

Rather than using visual cues from above, the ROV developed by Panetta and his team gauges the thickness of a slick by emitting sound waves from below—waves that reflect off the density boundaries between water and oil, oil and air, or oil and ice. Measuring the slight delay between the reception of these reflected echoes allows the vehicle’s software to gauge the thickness of surface and below-ice oil slicks at very fine resolution—from slicks less than 0.5 millimeters thick to more substantial accumulations of up to several centimeters.

Spread out over the vast expanse of a large spill—the Deepwater slick at one point covered 28,958 square miles—a difference of even a few millimeters in oil thickness can translate into a huge difference in spill volume.  Knowing the spill volume is a key factor in mounting an effective response, including decisions about applying enough—but not too much—chemical dispersant.

Knowing the spill volume is a key factor in mounting an effective response, including decisions about applying enough—but not too much—chemical dispersant.

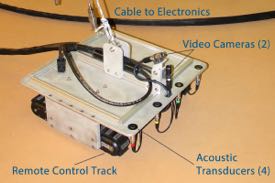

Working with Panetta to develop the ROV was VIMS visiting scientist Dale McElhone, along with John Oldfield and Wayne Reisner of VIMS’ Field Support Center, who helped to machine and design the small tank-like vehicle.

In addition to their studies at Ohmsett, where they investigated the vehicle’s performance with different crude oils and refined petroleum products, the team also tested the vehicle in William & Mary’s Adair swimming pool—using blocks of real ice—and in a 8,460-gallon tank in VIMS’ Seawater Research Lab, where they substituted thin sheets of hard plastic for ice, and Canola oil for crude.

“We built the ROV around waterproof motorized tracks,” says Panetta. “These are rated to a depth of 100 feet, have a top speed of 32 feet per minute, and can each pull up to 100 pounds.” Sitting atop the tracks is an aluminum platform hand-machined by Reisner and Oldfield that houses the vehicle’s sensors: 4 acoustic transducers to send and receive sound waves and 2 video cameras to help the human operator steer a safe and efficient path.

The ROV also contains a thermometer. “The speed of sound in water and oil changes with temperature,” says Panetta. “Knowing the temperature is thus an important parameter when using acoustic signals to determine a slick’s thickness.”

The ROV also contains a thermometer. “The speed of sound in water and oil changes with temperature,” says Panetta. “Knowing the temperature is thus an important parameter when using acoustic signals to determine a slick’s thickness.”

The ROV’s main electronics reside in a plastic case that stays topside. The ROV is tethered to the electronics by about 130 feet of cables. The controlling computer—a laptop with a joystick—connects to the electronics via Wi-Fi so that the operator can operate the electronics-ROV package from a pool-deck, or in the case of experiments at the Ohmsett tank, an observation tower.

The ultimate goal, says Panetta, is to continue refining the technology so that it can one day be used to help respond to an actual spill in the open ocean. “We’ve already thought of several improvements,” he says, “including integrating the video stream into the ROV software for more seamless operation. We’d also like to create a database of the acoustic properties of different types of oil as a function of temperature.”

Panetta says that future iterations of the technology might mount the sensors on an autonomous underwater vehicle or other free-swimming platform for greater flexibility and wider coverage. Another potential use of the equipment would be to send the acoustic signals sideways, to calculate the amount of oil leaking from a seafloor blowout. Determining the amount of oil escaping from the seafloor wellhead beneath the Deepwater Horizon drill rig was one of the most challenging aspects of the 2010 disaster.

Acoustic signals can also be used to determine the size range of oil droplets in a spill, a measure of whether applications of chemical dispersants have been effective. This is a topic the team has been pursuing at VIMS under a related contract from the Bureau of Safety and Environmental Enforcement.